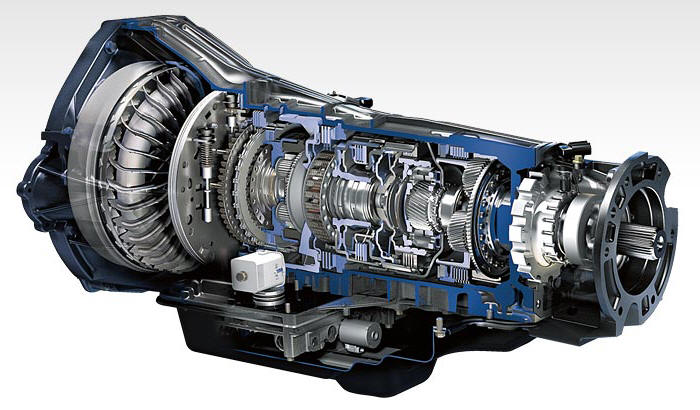

The automatic gearbox is the most complex part of the vehicle to which it is fitted.

How it works

Power is produced by the engine and transmitted to the automatic gearbox via the torque converter in most cars. This is a fluid coupling comprising of a pump, turbine, stator and clutch element. Oil is driven to the turbine by the pump at engine speed, thus spinning it and driving the gearbox. The oil is then directed through the stator, redirecting it back to the pump it the right direction and increasing the torque converters efficiency. The clutch element is a hydraulic piston with either a single or multiple clutch plate set up. This is engaged at higher speeds, locking the pump and turbine together an eliminating any slip in the torque converter providing better fuel economy and cooling. Slip in a torque converter is necessary when the car is stationary in drive or reverse and for pulling away, otherwise the car would stall the engine, but slip is inefficient so when the car is up to speed it is eliminated by engaging the clutch.

Power is produced by the engine and transmitted to the automatic gearbox via the torque converter in most cars. This is a fluid coupling comprising of a pump, turbine, stator and clutch element. Oil is driven to the turbine by the pump at engine speed, thus spinning it and driving the gearbox. The oil is then directed through the stator, redirecting it back to the pump it the right direction and increasing the torque converters efficiency. The clutch element is a hydraulic piston with either a single or multiple clutch plate set up. This is engaged at higher speeds, locking the pump and turbine together an eliminating any slip in the torque converter providing better fuel economy and cooling. Slip in a torque converter is necessary when the car is stationary in drive or reverse and for pulling away, otherwise the car would stall the engine, but slip is inefficient so when the car is up to speed it is eliminated by engaging the clutch.

The automatic gearbox is also hydraulically operated. The torque converter case is used to drive the oil pump in the front of the gearbox; this then provides the hydraulic pressure needed to apply the various clutch and brakes in the automatic gearbox, which in turn drive different gear sets in various combinations giving us the different gear ratios. All this is controlled by the valve body and/or the TCM(transmission control module). The valve body is the internal brain of the automatic gearbox. On early models it is fully hydraulic, using signals from a centrifugal governor, throttle position leavers and/or vacuum diaphragms to automatically change gear. Throughout the development of the automatic gearbox the valve body has become more and more electrical, starting with the addition of a few shift solenoids and speed sensors right up to what we see today, where the TCM is incorporated into the valve body, these units are now called Mechatonic units. Extreme care must be taken when handling these as even the smallest spark of static electricity will destroy the delicate circuitry rendering it useless.

Other variations of the automatic gearbox are the DSG and CVT.

DSG

The DSG is a duel clutch arrangement driving what are essentially two sets of manual gearbox shafts and pinions. The mechatronis unit pre selects the anticipated gear by hydraulically moving a selector inside the gearbox then swapping almost instantaneously from one clutch to the other, the next gear always being on the other shaft. This way the gear shift is much faster, therefore improving drivability and delivering better fuel economy.

CVT

The CVT is a constantly variable gearbox. This means it uses a chain and pulley system to achieve its different ratios. Gear changes are virtually undetectable in this kind of automatic gearbox, as one set of opposing pulleys close together; they pull the chain between them tighter, therefore forcing the driven set of opposing pulleys open. Because all the pulleys are at a constant flat angle the shifting is seamless. This kind of automatic gearbox provides better fuel economy and better power delivery than a standard automatic. A little known fact about the CVT is that it was first drawn by Leonardo DaVinci in 1490.

At Cajas Automaticas Transmatic our 20 years experience and highly skilled staff means we can take care of any automatic gearbox problem, small or large, vintage or modern, standard, DSG or CVT.